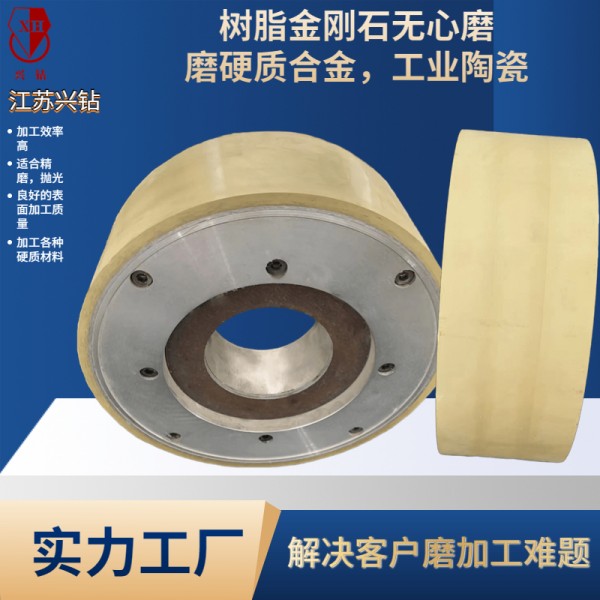

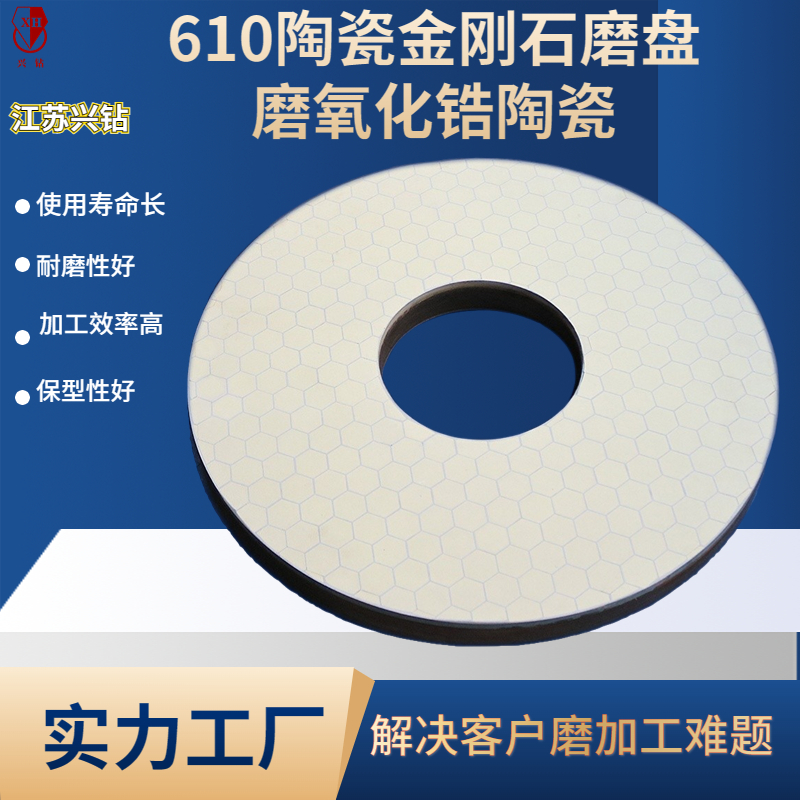

æ ?w¨¨i)èç è½®æ¯æç¨æ ?w¨¨i)èç»åååæçç è½®ï¼å æ¬éåç³ç è½®ï¼éåç³ç为磨æï¼åæ®éç 轮\_¼ åç½åçç为磨æï¼ãéåç³ç è½® æ¯ç¨éåç³äØ(f¨´)¼¨æåæçç è½®ï¼å ¶ä¸éåç³ç è½®æç §ç»ååæ¥ååQååï¼(x¨¬)æ ?w¨¨i)è¾lååç è½®ãéå±ç»ååç ãæ (w¨¨i)èéåç³ç è½®åçµ(sh¨´)ééåç³ç è½®ç主è¦åºå«å¨äº¾lååçä¸ååQæ (w¨¨i)èéåç³ç 轮主è¦éç¨é éæ ?w¨¨i)èå å°ééå±ç²ä½äØ?f¨´)¾lååï¼èçµ(sh¨´)ééåç³ç è½®æ¯éè¿ç|²¿U¯çæÒ(gu¨©)³®éé´åé沿U¯å¨éå±åÞZ½è¡¨é¢òq¶åºå®éåç³¼¨æç丿Uç è½®ç产工èºï¼ä»ã硬质åéç è½®æå¾å¤åç±»åQä¸é¢æ¯å ç§ä¸»è¦çå¾c R?ã?æ¶å±¼¬è´¨åéç è½®ã?ã?¼_é¬åº¼¬è´¨åéç è½®ã?ã?æ ?w¨¨i)èéåç³ç è½®ã丿U磨¼¬è´¨åéç¨æ (w¨¨i)èéåç³ç è½®å ähå¯ä»¥qè¡ä»¿åÅå®å¶ãææ¯å qãå¶é å¨æçãä¾è´§å¿«½{ç¹çV?ã?¼ëæ (w¨¨i)èç»ååéåç³ç è½®å ·æè¯å¥½çæå ä½ç¨åQ磨åæ¶ç è½®éå©åQä¸æå µå¡ï¼å ·ä½ç¹ç¹å¦ä¸åQ?ã磨åæçé«åQåæ¶ç è½®æ¶èç¸å¯¹è¾æ ¢ï¼2ãèªéæ§å¥½åQ磨åæ¶åçéå°åQä¸æå µå¡ï¼åå°äºç£¨åæ¶åºç°å·¥ä½ç§ä¼¤çç°è±¡ï¼3ãç è½®å ·æä¸å®çå¼Ò(gu¨©)§ï¼æ²¡å¾å¯Ò(gu¨©)¯åQæ (w¨¨i)èç è½®æ¯éåç³ç è½®éé¢ç丿Uå¶ä½å·¥èºï¼éåç³ç è½®å为ï¼éåç§ç»ãé¶ç÷æ (w¨¨i)èãçåQæä»¥ä½ è¯´çåºå«æ¯æ æ³å¯¹æ¯çãéåç³ç è½®æç»ååå¯å