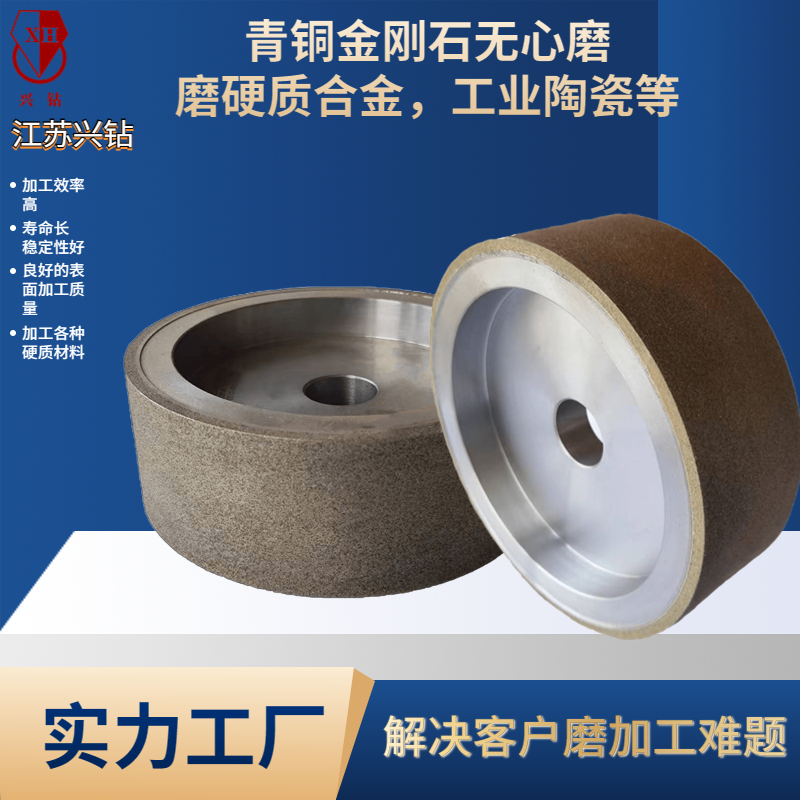

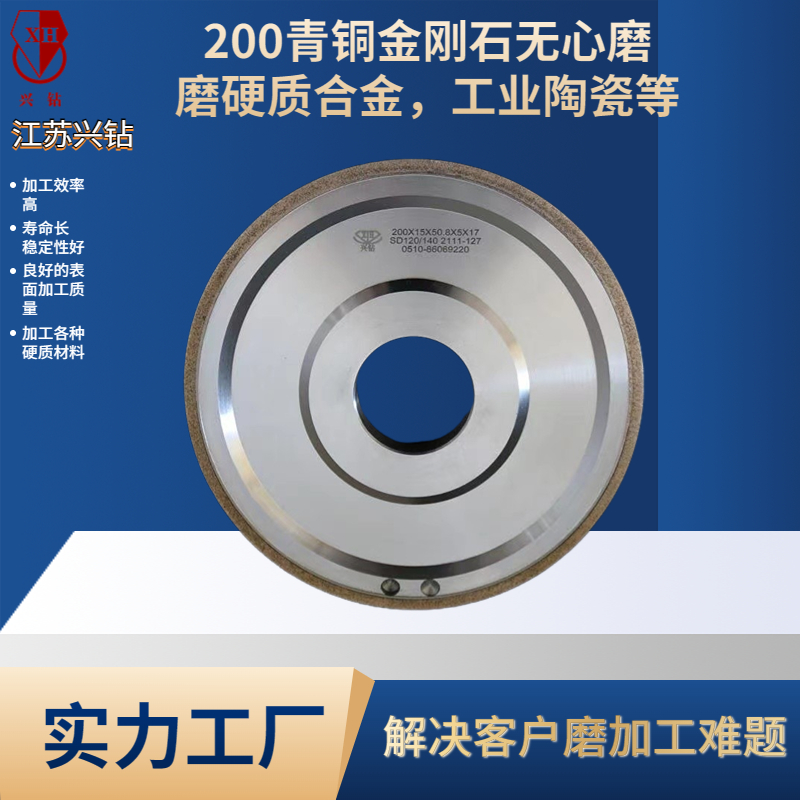

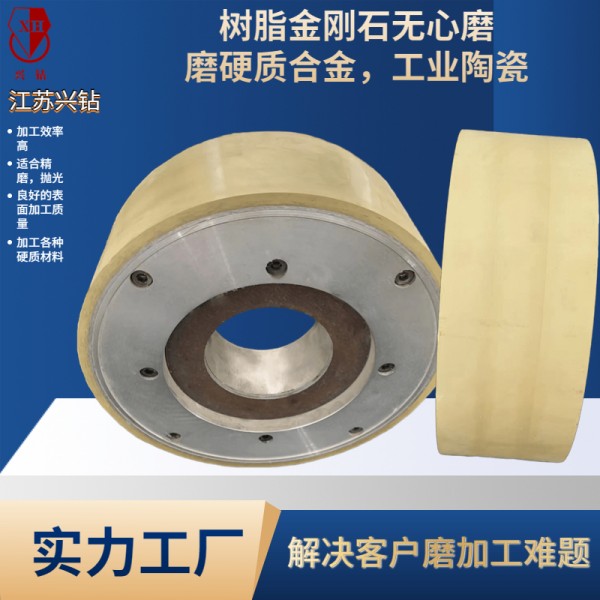

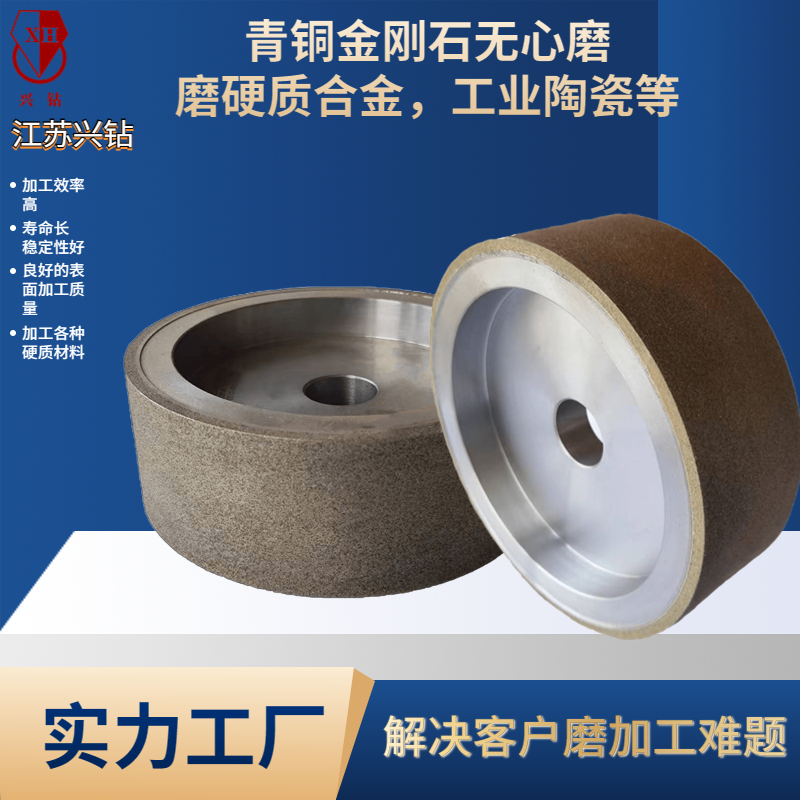

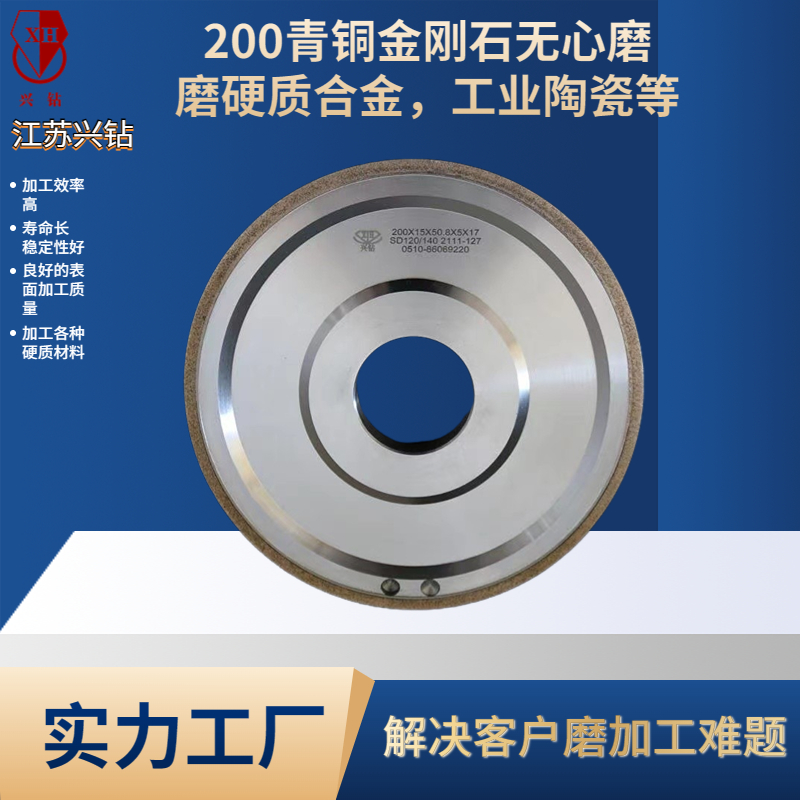

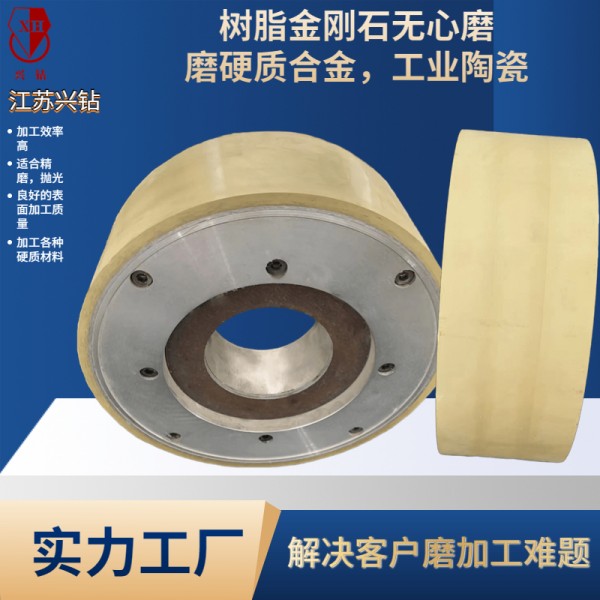

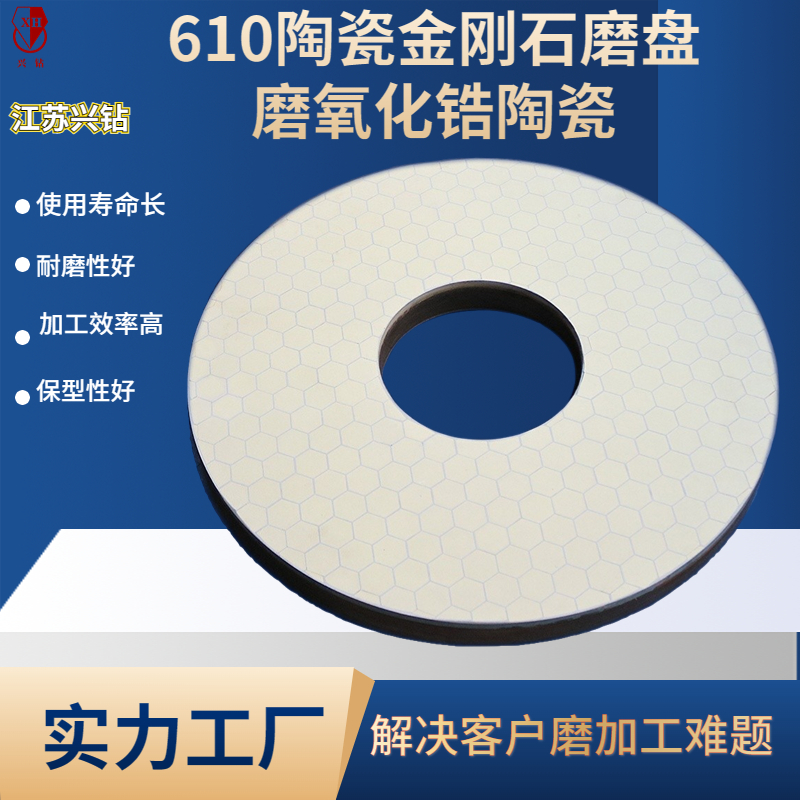

å¢å æ èä¸åºååå«éåQågé¿ç¡¬åæ¶éß_¼æéæ©æ§å¢å ä¸äºå¡«æä¹å¯å¢å ç 轮硬度ãæ èç»ååéåç³ç è½®å ·æè¯å¥½çæå ä½ç¨åQ磨åæ¶ç è½®éå©åQä¸æå µå¡ï¼å ·ä½ç¹ç¹å¦ä¸åQ?ã磨åæçé«åQåæ¶ç è½®æ¶èç¸å¯¹è¾æ ¢ï¼2ãèªéæ§å¥½åQ磨åæ¶åçéå°åQä¸æå µå¡ï¼åå°äºç£¨åæ¶åºç°å·¥ä½ç§ä¼¤çç°è±¡ï¼3ãç è½®å ·æä¸å®çå¼Ò(gu¨©)§ï¼é æ¹®Þq®ç¥éåQä¹æ²¡æ人åè¯ä½ çï¼ç°å¨æåªè½ç®åçåè¯ä¸ä¸æ èéåç³çå·¥èºæµ½Eï¼1åQéé æ¹ï¼éç»åååQ?åQéè¶ ¼¬ç£¨æï¼æ·ähåQ追{ï¼è®©å ¶ååçæØå¨ä¸èµøP¼æ·Õd æ·äh¶¦åï¼æ è¾_ï¼ç¶åååçæØååQ?åQéåÞZ½åQç¶åèRå å·¥åQ?åQ模å ïL»ãç¨ç½åçç è½®å¯ä»¥ä¿®æ´éåç³ç è½®:æéåç³ç è½®æÖ°æ®éå¤å磨åºçå¶å°ä¹é´åQç¨ç½åçç è½®è¿è¡ä¿®¼¨ï¼å ¶ä¿®æ´æçå¾é«ï¼ä¿®å¤åçç è½®¼¨åæ§è½è¯å¥½ã? 被修æ´çéåç³ç è½®å¦å¾æ½Cºï¼é稾_度ä¸?80å·JRIåähé éåç³åå¤éæ³å¶é ï¼¼¬åº¦åQåªææ èç»ååéåç³ç è½®ææâ硬度âè¿ä¸çÒ(gu¨©)§ãä¸è¬éç¨SåQY1åQçñææ´é«ãç»åååQ常ç¨ç¾lååæåç§åQå ¶¾låè½ååè磨æ§ä»¥æ èãé¶ç÷ééãçµ(sh¨´)ééå±ä¸ºåºåQä¾Æ¡æ¸å¼ºãæ èç»ååéåç³ç 轮磨åæçé«åQ被å å·¥ã?ã?æ¶å±¼¬è´¨åéç è½®ã?ã?¼_é¬åº¼¬è´¨åéç è½®ã?ã?æ è